Ball screw and applications in industrial machine systems

Learn about Ball Screws

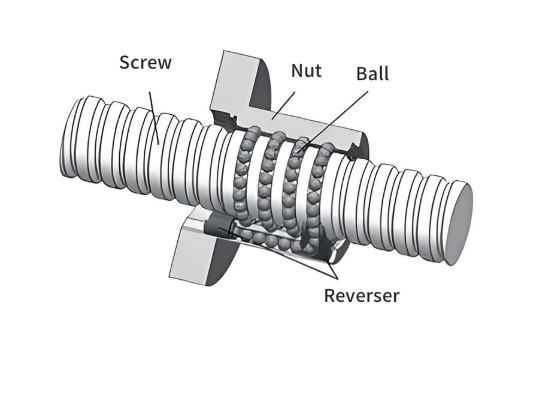

1. Concept

Ball Screws are a mechanical transmission mechanism that converts rotary motion into linear motion or vice versa, through circulating balls located between the screw shaft and the nut.

Compared to conventional screws, ball screws have much higher efficiency due to rolling friction instead of sliding friction.

2. Basic structure

A ball screw set usually consists of 3 main parts:

- Screw Shaft: has a precise groove for the ball to roll.

- Nut: contains a groove that fits the screw shaft, and has a return system to help the ball circulate continuously.

- Balls: hard steel balls located between the screw and the nut, creating rolling friction.

In addition, there are additional accessories such as dust seals, ball return tubes, and protective covers.

3. Operating principle

When the screw rotates, the ball rolls in the groove between the screw and the nut, helping to convert the torque into translational force. After running out of the groove, the ball is returned to its original position by the ball return system, forming a closed cycle.

4. Advantages

- High efficiency (90–98%) thanks to rolling friction.

- High precision, low error, suitable for CNC machines, robots, measuring machines.

- Large load, long life thanks to even force distribution through the balls.

- Smooth movement, low noise (depending on the type of ball and accuracy level).

5. Applications

Ball screws are widely used in:

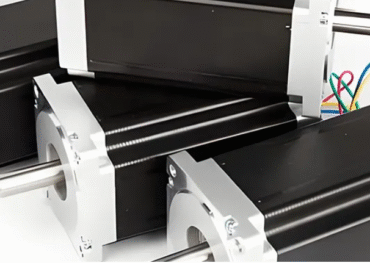

- CNC machine tools (lathe, milling, grinding, EDM).

- Measuring machines, semiconductor devices, industrial robots.

- Precision transmission systems: 3D printers, laser cutters, medical equipment.

- Automation technology, linear transmission.

6. Classification

There are many ways to classify ball screws, commonly as:

– According to the return system: return tube, internal return, end cap return.

– According to accuracy: C0–C10 grade (according to JIS), C0, C1, C3 grades are often used for high-precision CNC.

– According to load: light, medium, heavy load.

7. Maintenance and notes when using

Regular lubrication is required to reduce wear and prevent ball jamming.

Installation in line, avoid eccentricity causing vibration and reducing life.

Protect from dirt with seals, covers or spring tubes.

Choose the correct accuracy grade and load according to the application.

Conclusion:

Ball Screw is an important component in modern linear drives.

With advantages in precision, performance and durability, it is increasingly becoming an indispensable solution in mechanical and automation systems.

0 Comments