SENYA's air control valve is a device that controls the flow of compressed air, thereby controlling the speed of movement of pneumatic cylinders in automation systems.

It is also called flow control valve or speed controller. Here is an overview :

Main function:

- Adjust the flow of exhaust gas or gas into the cylinder to control the forward/reverse speed of the piston.

2. Stabilize the movement and reduce vibration or shock in the system.

3. Optimize the operation process, ensure the performance and life of the equipment.

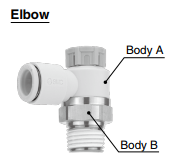

Basic structure:

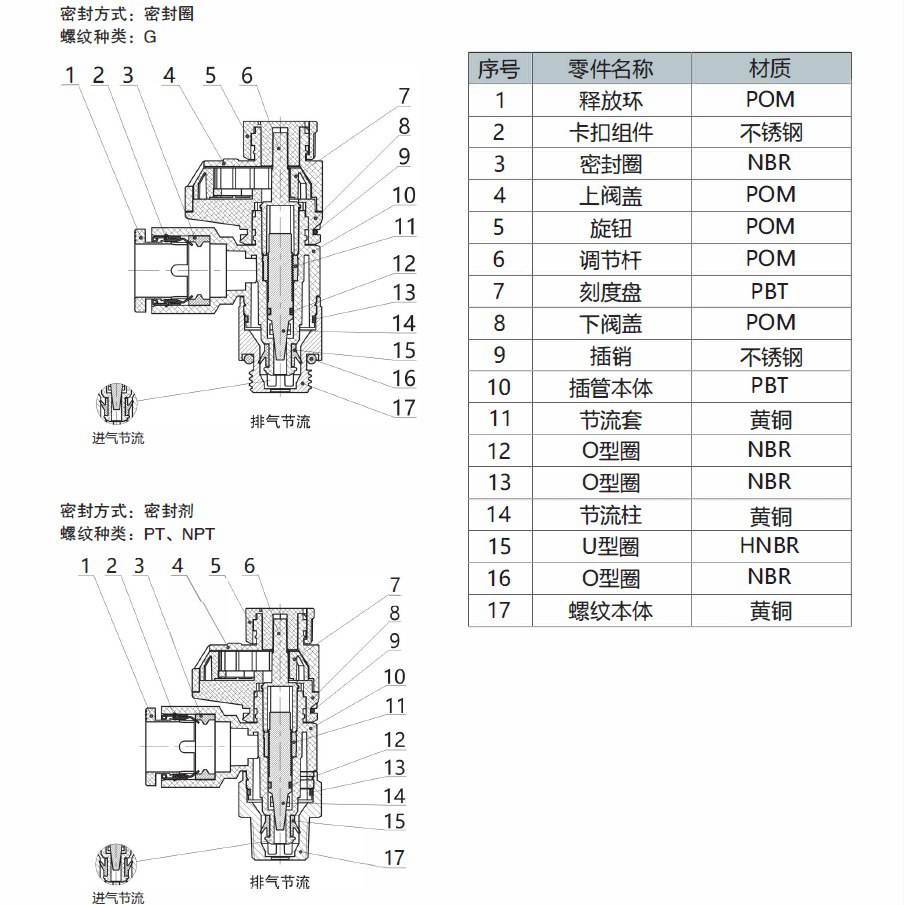

- Needle valve: Used to change the cross-section of the gas flow, adjust the flow.

- Check valve: Allows gas to flow in a certain direction (controlled or free).

- Threaded or push-in fitting: Connects to the gas pipe.

Outstanding features of SENYA Air control valve:

- Compact design, easy to install and maintain.

- Has the function of controlling one-way air flow (eg: control when the piston advances, but allows air to escape quickly when the piston retreats).

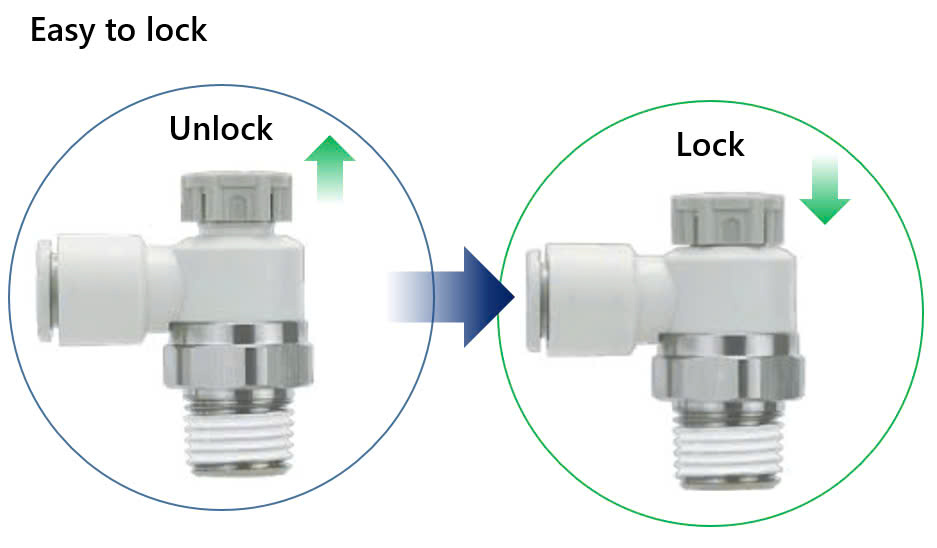

- Some models have an adjustment lock button to prevent unwanted changes.

- Integrated turn indicator ring helps to adjust the flow more accurately.

Classification (by installation method):

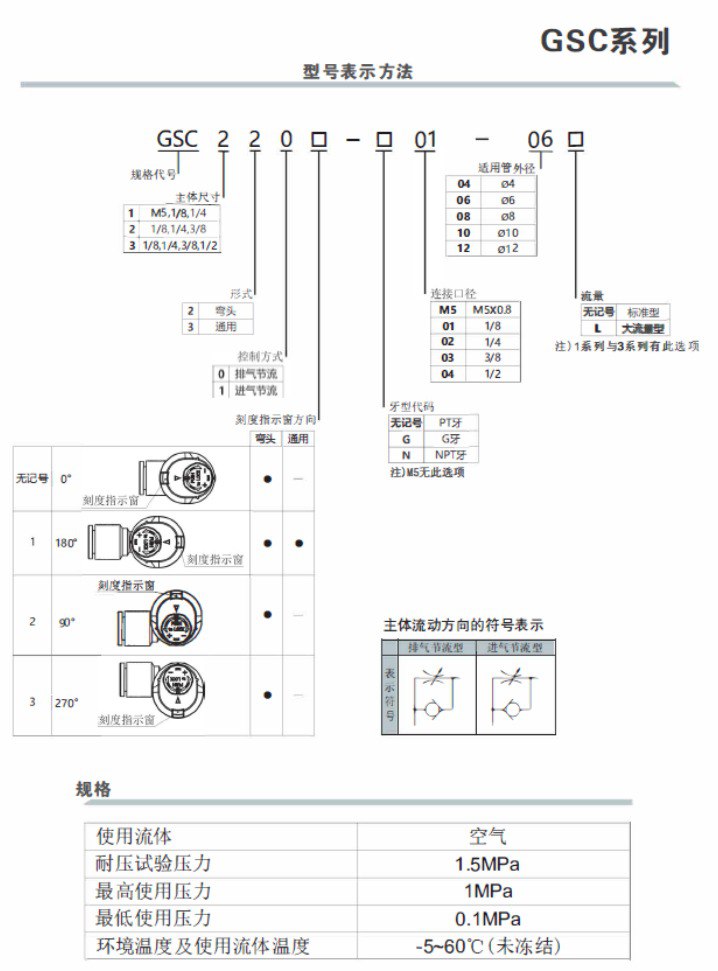

- GSC series (standard): Valve with speed control function, mounted directly on the cylinder.

- GSC-FS, GSC-FG (plug-in or inline): Intermediate installation type on the pipeline.

- GSC speed controller with one-touch fitting: Type with quick connector, easy to install.